Designed With The Professional Gel Candle Maker In Mind

Our EZGEL dispensing systems offer

-

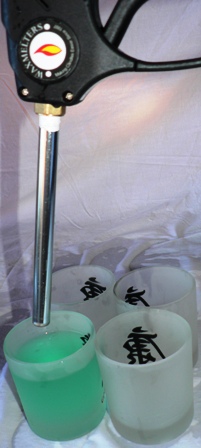

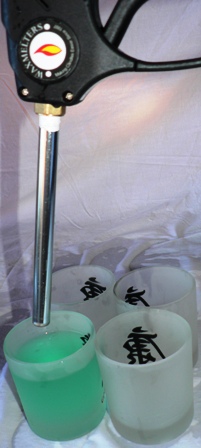

Fast, controlled adjustable filling with no air bubbles or dripping- a steady rapid safe and controlled flow of gel for gel candle making from 175° F/ 79° C to 212° F/ 100 ° C.

-

Heated Pump, Hose and heated thermo gun keep your Gel heated and fluid during filling.

-

Smooth Bore Teflon® heated hose which is chemical, temperature and shock resistant, while being lightweight, flexible, non-contaminating, non-adhesive and moisture and deterioration resistant.

-

Digital temperature controller is easy to read and use and features a liquid crystal display (LCD) to provide accurate, precise heating from 175° F/ 79° C to 212° F/ 100 ° C, light-emitting diode (LED) to indicate On/Off status, easy fingertip-touchpad which has lockable feature and allows easy set up and adjustment of control setpoint, differential, and other functions, and is enclosed in high-impact resistant, thermoplastic NEMA 4X watertight, corrosion-resistant surface-mount enclosure.

-

Simple and easy to set up and operate!

-

Heated thermogun keeps all your products hand poured and handmade with the speed, precision and efficiency of manufacturing.

-

An easy and virtually waste free self-cleaning mechanism for quick color & scent changes.

Real world competency with technical solutions: Our EZGEL Professional Gel candle filling equipment and machines have been a life saver to our long list of customers in the Gel Candle industry.

EASY SET UP- JUST 4 STEPS (plus plug in unit for electrical power):

|

STEP 1 |

STEP 2 |

STEP 3 |

STEP 4 |

|

|

|

|

|

Thermopump to Melter |

Hose to Thermopump |

Thermogun to Hose |

Nozzle to Thermogun |

HOW FAST DO THESE WAX DISPENSING SYSTEMS POUR?

All wax dispensing systems are rated for 1 gallon or more per minute! In addition, thermogun's trigger allows you to reduce the flow rate or you can adjust it by reducing the opening of the ball valve at your melter.

| SYSTEM-MAXIMUM FLOW RATES |

CUP/ .24 Liters |

QUART/.95 Liters |

GALLON/3.79 Liters |

| EZGEL |

4+ Seconds |

15+ Seconds |

60+ Seconds |

*DISCLAIMER: All flow rates shown above are at maximum rate and flow rate may vary based on material being dispensed, user proficiency, amount of material being dispensed, melter attachments like using a 90 degree nozzle, operating conditions, operating without sufficient electricity, operating prior to materials being fully melted, and so on.

IS IT EASY TO CONTROL FLOW RATE?

|

Heated Thermogun's trigger and safety lock allow you to quickly and easily reduce the flow rate to only a small drizzle or you can adjust the flow rate by reducing the opening of the ball valve at your melter. |

VIRTUALLY DRIP FREE

|

Our EZGELsystem is designed for stop & go dispensing and by keeping the nozzle almost straight down, you can eliminate virtually any drip.

SMOOTH, RAPID FILLING WITHOUT BUBBLES. |

EZ 3 STEP CLEANING FOR COLOR AND/OR SCENT CHANGE:

| STEP 1 |

STEP 2 |

STEP 3 |

|

|

|

| Once you finish filling, shut off the ball valve at the tank and pull the hand trigger on the handgun for a few seconds. This will purge existing product from the lines. |

When Melter is empty, wipe out the melter to absorb any remaining colors and scents in the tank. |

Melt your next batch and dispense a few ounces until only your new batch starts pouring. This will clean any existing color and scent from the lines. |

IT'S EZ, FAST AND VIRTUALLY WASTE FREE!

WHAT IS SO SPECIAL ABOUT YOUR TEFLON® HOSES?

Unique hand assembly makes sure that your hose is working at the optimal level. Each hose is flexible, heated with the finest quality, efficient heating source and of course the welded, Teflon® Core makes our hoses are:

-

Chemical Resistant: Inert to practically all commercial chemicals, acids, alcohols, coolants, elastomers, hydrocarbons, solvents, synthetic compounds and hydraulic fluids.

-

Temperature Resistant: Rated for 406 degrees F with low volumetric expansion characteristics, so it is easy to clean, sterilize and with not retain particles, colors or scents.

-

Shock Resistant: Not affected by continuous flexing,vibration, impulse pressure or alternating hot and cold cycling.

-

More Flexible & Lightweight than Rubber: Easier to move, handle and install than rubber hose!

-

High Flow Rates: Flow coefficient of friction of Teflon® and anti-stick properties lowers pressure drop while maintaining good service pressures.

-

Non-Contaminating: Will not contaminate material, fluid or gas conducted - Teflon® is an FDA recognized material for food handling and pharmaceutical applications.

-

Non-Adhesive: Easy handles substances like adhesives, asphalt, dyes, greases, glue, latex, lacquers and paints.

-

Moisture Resistant: No moisture absorption, ideal as a pigtail in bulk gas handling and pneumatic systems where a low dew point is critical.

-

Long Lasting: Impervious to extended use, climate, and can be stored for extended periods of time without aging.

IS THE SYSTEM SAFE? HOW LONG DOES IT LAST?

-

Our hoses are rated for continuous exposure temperatures of 250° F (121°C), but since our digital controllers limit temperature to a maximum of 212° F (100°C), degrees you have even extra protection and extended life.

-

Hoses are wired with parallel circuit, low watt density electric heating with a conductive polymer core that with our sensors regulate heat output to prevent overheating, hot spots or causing burn outs in response to changes in surface and ambient temperatures.

-

All hoses have a dielectric strength over 2000 volts and have internal stainless steel overbraid for additional mechanical protection and a low resistance path to ground as required by NEC 427-23.

HOW WILL IT INCREASE PRODUCTION AND REDUCE WASTE?

Imagine a day worry free - you would never have to lift a pouring pitcher again. You would never have to walk from table to table with potentially dangerous hot wax or worry about spills and clean up. With our systems, it is almost like you are bringing your wax melting tank nozzle with you except it is much lighter and our wax dispensing systems make a much faster, yet bubble-free, safe and controlled flow.

ARE PEOPLE USING THIS SYSTEM? ISN'T IT EASIER TO STICK WITH WHAT I KNOW?

We are all for traditional, natural ways of doing things, but imagine what your reaction would be if you went to the register at a supermarket with a cart full of groceries and the cashier took out a pencil and paper to check you out? If you are still hand pouring your candles and/or soaps, it is like you mowing your lawn with a push reel mower. Best of all, with our wax dispensing systems, your candles are still "handmade" by you and your company.

A SIMPLE TEST TO SEE IF YOU ARE MAXIMIZING YOUR BUSINESS PRODUCTION:

WHICH EQUIPMENT WOULD YOU BUY IF YOU HAD A LAWN MOWING BUSINESS?

|

|

OR |

|

| WHICH EQUIPMENT WOULD YOU BUY IF YOU HAD A CLOTHING BUSINESS? |

|

|

OR |

|

| WHICH EQUIPMENT WOULD YOU BUY IF YOU HAD AN ICE CREAM BUSINESS? |

|

OR |

|

|

|

|

WHICH EQUIPMENT ARE YOU USING FOR YOUR BUSINESS?

YOU OWE IT TO YOURSELF & YOUR BUSINESS TO CHANGE FOR THE BETTER...

IMAGINE a cost effective, worry free way of being able to make 2X as many candles and soaps in less time with less waste and with less back, shoulder, neck and hand aches and pains. If you have employees, then you know labor costs are very high so being able to increase your production reduces the time and money spent on employee training, retaining and most of all, employees walking to and from the pouring table with full pouring pitchers. This old fashion way is expensive. Plus our systems reduce clean-up on overspills on jars! Plus, increasing productions opens the door for additional business.

Customers all over the world are using our wax dispensing systems and have increased their production and reduced waste dramatically, some as much as by 50% more production and 75% less waste.

SO ARE YOU READY TO SUPER-CHARGE YOUR PRODUCTION?

ORDER TODAY TO MAXIMIZE YOUR TIME AND EFFORT WITH MORE PRODUCTION!

|